How to adjust the fineness of calcium hydroxide equipment?

Users who purchase calcium hydroxide equipment production lines usually consult in detail about what standard the calcium hydroxide produced by calcium hydroxide equipment can meet, and purchase corresponding supporting production lines according to their own goals.

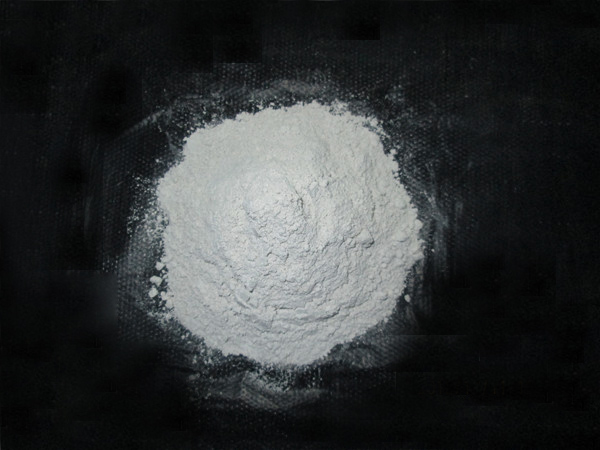

At present, the calcium hydroxide powder produced by domestic calcium hydroxide equipment can reach industrial grade use, the fineness is generally 200-400 mesh, and the content is generally 65%-93%. construction and other industries.

The fineness of calcium hydroxide equipment can reach about 325 mesh, and it can produce 6-20 tons of finished calcium hydroxide per hour. If it is produced in 24 hours, it can produce up to 480 tons of calcium hydroxide powder a day, which can meet the high standard requirements of users.

How to ensure the powder fineness of calcium hydroxide equipment?

For the performance of calcium hydroxide equipment, powder fineness is undoubtedly a very important measure. Users all hope that the purchased equipment can achieve stable powder fineness and ensure powder quality. From the following two aspects to ensure that users buy Equipment to the desired effect and standard.

1. The matching powder selection device is very important. Its main function is to classify and screen the powder processed by the calcium hydroxide equipment, and select qualified finished products. Therefore, for the calcium hydroxide production line, choose the selection that is suitable for your own production line requirements. The size of the powder machine becomes very important.

Calcium hydroxide production line manufacturers will design the best supporting facilities according to the needs of users and comprehensive factors.

2. In the calcium hydroxide production process, the importance of the lime digester cannot be ignored. The calcium hydroxide production line must continuously combine advanced technology to innovate and upgrade the performance of the lime digestion process, so that the raw materials can be quickly and fully reacted inside the machine. achieve the desired granularity.

How to adjust the fineness of calcium hydroxide grinding equipment?

In the production of calcium hydroxide mill, its own processing fineness requirements are mainly adjusted within a certain range according to user needs. Some customers consulted in the production process, the fineness of calcium hydroxide grinding equipment is not well controlled, and the particle size often does not meet the standard. So what are the methods to improve the processing fineness of calcium hydroxide mill? Let’s find out together.

When the calcium hydroxide mill is in use, its main motor adopts frequency conversion speed regulation, so that the spindle speed can be greatly adjusted, thereby changing the centrifugal force of the grinding roller pressing against the grinding ring and changing the grinding effect. Mainly to further increase the output after grinding the coarse powder, the power of the main engine and the blower motor is appropriately increased.

The swing position of the grinding roller of the calcium hydroxide mill is effectively limited, so that a gap is formed between the grinding roller and the grinding ring during operation, and the gap can be adjusted at will, so that the grinding intensity can be greatly adjusted and the particle size can be controlled. At the same time, for the adjustment of the air supply system, the internal air speed and air volume can be adjusted, so that the air selection particle size is proportional to the flow rate of the wind wheel.