Gaifeng Hydroxide Production Line Delivery

Gaifeng hydroxide production line delivery! As a professional calcium hydroxide production line manufacturers, the equipment has been well received by users.

Features of Gaifeng Hydroxide Production Line

1. High Automation & Efficiency

Fully automated control system (PLC or SCADA) for real-time monitoring.

Continuous production process with minimal manual intervention.

High efficiency with reduced energy consumption.

2. Advanced Hydration Technology

Uses high-performance hydrators to ensure complete and uniform reaction between quicklime and water.

Adjustable hydration temperature and reaction time for different quicklime qualities.

High-speed mixing to prevent unreacted lime particle.

3. Dust & Pollution Control

Equipped with pulse dust collectors, bag filters, and water dust suppression systems to minimize dust emissions.

Complies with environmental regulations for dust-free and low-noise operation.

4. Precise Water Dosing System

Automatic water dosing to achieve the optimal Ca(OH)₂ yield and prevent over-hydration or under-hydration.

Intelligent water control system for stable product quality.

5. Grinding & Classification System

Fine grinding mills (raymond mill, ball mill, or hammer mill) to achieve the desired particle size.

Air classifier for sorting particles into different grades based on application requirements.

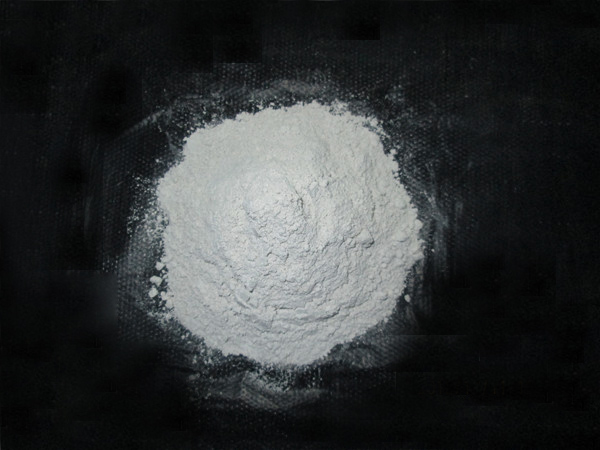

6. High Purity & Uniform Particle Size

Efficient separation and removal of impurities such as magnesium oxide and unreacted CaO.

Customizable mesh sizes (e.g., 200-400 mesh) based on industry needs.

7. Energy-Saving & Heat Recovery System

Some production lines use waste heat recovery to reduce energy consumption.

Optimized power usage with energy-efficient motors and variable speed drives.

8. Customizable Design for Different Capacities

Available in small, medium, and large-scale production capacities (from a few tons to hundreds of tons per day).

Can be integrated with lime kilns for a complete quicklime to calcium hydroxide processing system.

9. Storage & Packaging Solutions

Automated conveying, storage, and bagging systems for bulk or small-packaging distribution.

Can include big bag filling, valve bag packaging, or silo storage for large-scale operations.

10. Applications & Industry Adaptability

Used in various industries such as construction, chemical, environmental protection, food processing, water treatment, and agriculture.

Can be modified to meet specific industry standards like pharmaceutical-grade or food-grade calcium hydroxide.