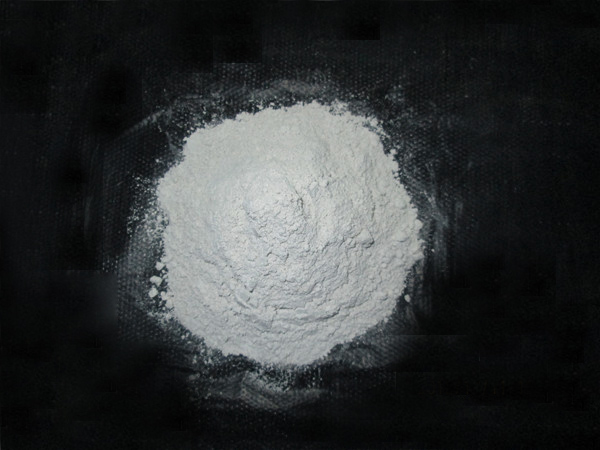

Carbon Dioxide Adsorbent

A carbon dioxide adsorbent is a material that has the ability to selectively capture and hold carbon dioxide molecules from a gas or liquid mixture. These adsorbents can be used in a variety of applications, including carbon capture and storage, air purification, and gas separation.

Carbon dioxide adsorbents work by attracting and binding carbon dioxide molecules to their surfaces. The adsorption process can be influenced by various factors, including the surface area, pore size, and chemical composition of the adsorbent, as well as the temperature and pressure of the gas or liquid mixture.

There are many different types of carbon dioxide adsorbents, including zeolites, activated carbon, metal-organic frameworks (MOFs), and porous polymers. Each of these materials has its own unique properties and advantages, such as high adsorption capacity, selectivity, stability, and regeneration ability.

Carbon dioxide adsorbents are materials that have the ability to selectively capture and hold carbon dioxide molecules. These adsorbents can be used in various applications, such as carbon capture and storage, air purification, and gas separation.

There are many different types of carbon dioxide adsorbents, including zeolites, activated carbon, metal-organic frameworks (MOFs), and porous polymers. Each of these materials has its own unique properties and advantages.

Zeolites are crystalline materials that have a regular, porous structure. They have been extensively studied for their ability to adsorb carbon dioxide and are commonly used in industrial processes.

Activated carbon is a highly porous material that is widely used for gas purification and separation. It can be modified to increase its carbon dioxide adsorption capacity.

MOFs are a relatively new class of materials that are composed of metal ions or clusters linked by organic ligands. They have large surface areas and can be tailored to have specific properties, including high carbon dioxide adsorption capacity.

Porous polymers are another class of materials that have been studied for their carbon dioxide adsorption properties. They are lightweight and have high surface areas, making them attractive for applications such as gas separation.

Carbon dioxide adsorbent performance

The performance of carbon dioxide adsorbents is typically evaluated based on their carbon dioxide adsorption capacity, selectivity, stability, and regeneration ability.

Adsorption capacity is a measure of how much carbon dioxide the material can capture per unit mass. This property is influenced by factors such as the surface area, pore size, and chemical composition of the adsorbent.

Selectivity is a measure of how well the adsorbent can differentiate between carbon dioxide and other gases in a mixture. This property is important for applications such as carbon capture and storage, where the adsorbent needs to capture carbon dioxide from flue gas or other industrial emissions.

Stability is a measure of how well the adsorbent can maintain its carbon dioxide adsorption performance over time, even in harsh conditions. Adsorbents that are unstable may degrade or lose their adsorption capacity over time, reducing their effectiveness.

Regeneration ability is a measure of how well the adsorbent can release the captured carbon dioxide and be reused for subsequent cycles. Efficient regeneration is important for applications such as carbon capture and storage, where the captured carbon dioxide needs to be released and stored or utilized.