Calcium Hydroxide Manufacturing Process

Calcium hydroxide, also known as hydrated lime or slaked lime, is a chemical compound with the chemical formula Ca(OH)2. It is produced by the reaction of calcium oxide (lime) with water, a process known as slaking.

The manufacturing process of calcium hydroxide typically involves the following steps:

Quicklime production: Calcium hydroxide is produced from quicklime, which is made by heating limestone to high temperatures in a kiln.

Slaking: Quicklime is added to water in a slaking tank, where it reacts with the water to form calcium hydroxide. The slaking process generates heat and produces a lot of steam, so the reaction is typically carried out in a specially designed slaking tank with a mixer and a venting system.

Separation and filtration: After slaking, the mixture of calcium hydroxide and water is allowed to settle, and the excess water is decanted off. The remaining slurry is then filtered to remove any impurities.

Drying: The filtered calcium hydroxide slurry is then dried in a rotary or fluidized bed dryer to remove any remaining moisture.

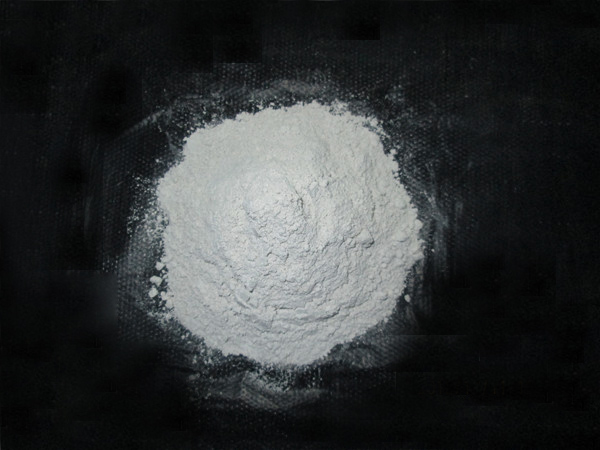

Packaging: The dried calcium hydroxide powder is then packaged and shipped for use in various applications.

Overall, the manufacturing process of calcium hydroxide is relatively simple and involves the reaction of quicklime with water, followed by separation, filtration, drying, and packaging. Calcium hydroxide is widely used in various industries, including construction, agriculture, and chemical manufacturing, due to its alkaline properties and ability to react with acids.