Tips:

⑴The raw materials are measured from the via the and then enter the , and then fall into the through the .

⑵The raw materials are mixed with water in the first digester of the ashing machine, and the pre-digestion reaction is carried out through stirring, and then sent to the second digester.

(3) The pre-digested materials are digested again in the and sent to the .

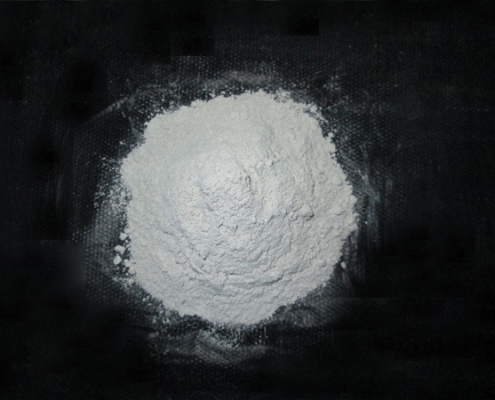

⑷The semi-digested raw materials are fully stirred and reacted by the . Using the heat generated by itself, the excess water in the material is evaporated, and the mixture of calcium hydroxide powder and impurities (non-reactive substances such as raw burnt and quartz) that is lower than the dew point (75°C) is discharged.

⑸The mixed material is discharged from the at the lower end of the , and is sent to the inlet of the powder concentrator through the lifting equipment.

⑹There is a special dust collector at the upper end of the that works under high alkali and humid conditions. This dust collector releases and discharges the steam pressure generated during the exothermic reaction of digestion and sends it to the heat exchange System> to form a negative pressure inside the entire digestion unit to avoid leakage of steam and dust. The filtered wet powder is directly returned to the and mixed with other materials.

⑺The discharged hot air containing water vapor is exchanged by the , which partially reduces the water vapor, heats the equipment water, and uses hot water as production water into the .

⑻ can adjust the fineness on-line, selects the powder whose fineness is higher than the set fineness, and sends it to the through four separate The conveying finally reaches the finished product tank, and the powder with the fineness lower than the set fineness is discharged, and sent to the slag discharge screw via the and finally arrives at the ash storage.

⑼ is designed for self-circulating air, and there is no gas emission during use. It is equipped with a small , which pumps the entire into negative pressure to achieve the goal of no dust and leakage.